Decarbonizing the Steel Industry – Trends, Assessing Technologies, Challenges and Case Studies

Powered by ![]()

All the vital news, analysis, and commentary curated by our industry experts.

Decarbonizing the Steel Industry Report Overview

Steel accounts for 9% of global CO2 emissions and is considered a hard-to-abate industry. Amidst strong forecast growth over the coming decades, major changes need to be implemented to get steelmaking on track and in line with the Paris Agreement. Secondary-stream steelmaking recycles scrap steel and makes up around 30% of global steel production. The recycling rate for steel is estimated by the World Steel Association at 85% with limited room for improvement. Increased electrification will reduce the steel industry’s reliance on coal, which currently makes up around 75% of energy and feedstock demands. Electrification can be achieved by replacement of direct reduction of iron with HDRI or electrolysis, as well as by increased secondary stream steelmaking which now commonly utilizes the electric arc furnace (EAF) to fire scrap steel.

This report assesses the steel sector’s current emissions footprint and its emissions reduction targets. It also explores the potential and limitations of the steel sector’s foremost decarbonization technologies: Green hydrogen for HDRI steel, carbon capture utilization and storage, and refining steel via electrolysis.

| Key Decarbonization Technologies | Green Hydrogen for HDRI Steel, Carbon Capture Utilization and Storage, and Refining Steel Via Electrolysis |

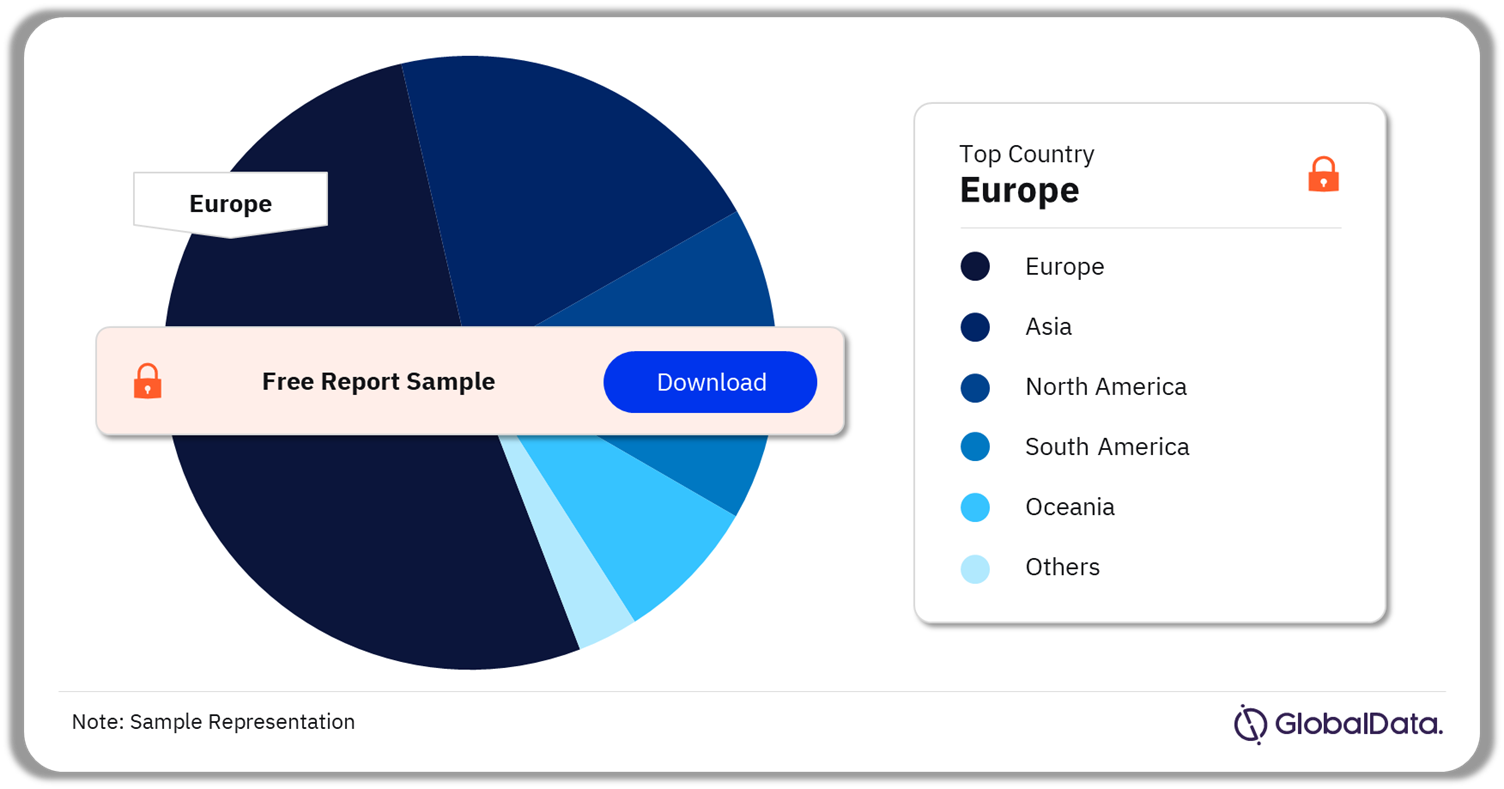

| Key Countries (HDRI) | Europe, Asia, North America, South America, Oceania, Middle East, Former Soviet Union, and Africa |

| Enquire & Decide | Discover the perfect solution for your business needs. Enquire now and let us help you make an informed decision before making a purchase. |

Buy the Full Report for Additional Trends in the Decarbonizing the Steel Industry

Steel Emissions

Steel contributes to 9% of CO2 emissions globally (EPRS), with coal used in the direct reduction of iron ore (DRI) being the highest emitting stage in steelmaking. Coal makes up around 75% of the energy and feedstock demands of the sector according to the IEA. To keep emissions in line with the Paris Agreement, the industry must cut emissions by 93% before 2050.

Emissions have increased over the past decade, and this rise is only expected to continue with population and economic growth, but also with the energy transition as steel is required for electric vehicles, wind, and solar power generation. Decarbonization through energy efficiency improvements to steelmaking is more cost-effective, making it more attractive to steelmakers, but achieves smaller emission reductions. Primary production through innovative technologies needs to be implemented to achieve substantial emissions reductions. This report will explore the potential of some of these technologies.

Buy the Full Report for More Insights on Steel Emissions

Download the Free Sample Report

Decarbonizing Technologies in the Steel Industry

The key decarbonizing technologies of the steel industry are Hydrogen Direct Reduction of Iron (HDRI), CCUS, and Electrolysis.

Hydrogen Direct Reduction of Iron (HDRI): HDRI replaces coal with hydrogen in reducing iron ore to yield pure iron. Instead of producing CO2 as a byproduct, hydrogen as the reducing agent produces water. Decarbonization utilizing HDRI relies on an infrastructure that supplies green hydrogen, which is produced by electrolysis of water using renewable electricity. HDRI has been proven to be viable on a commercial scale but is most convenient in that natural gas can be used as a bridging technology – already achieving 50-60% reductions in emissions in the meantime before green hydrogen becomes accessible and affordable.

The global hydrogen capacity is set for a CAGR of 67.7% between 2023-2030. The majority of announced green steel projects use HDRI, and in 2022 the European Commission (EC) identified a strong trend in the steel industry based on the technology. Europe is the current leader with the most active plants and the greatest project pipeline. Scandinavia, Germany, and Austria have been particularly proactive and recently Spain has increased its project pipeline to four.

Hydrogen Iron and Steel Projects by Region, 2023 (%)

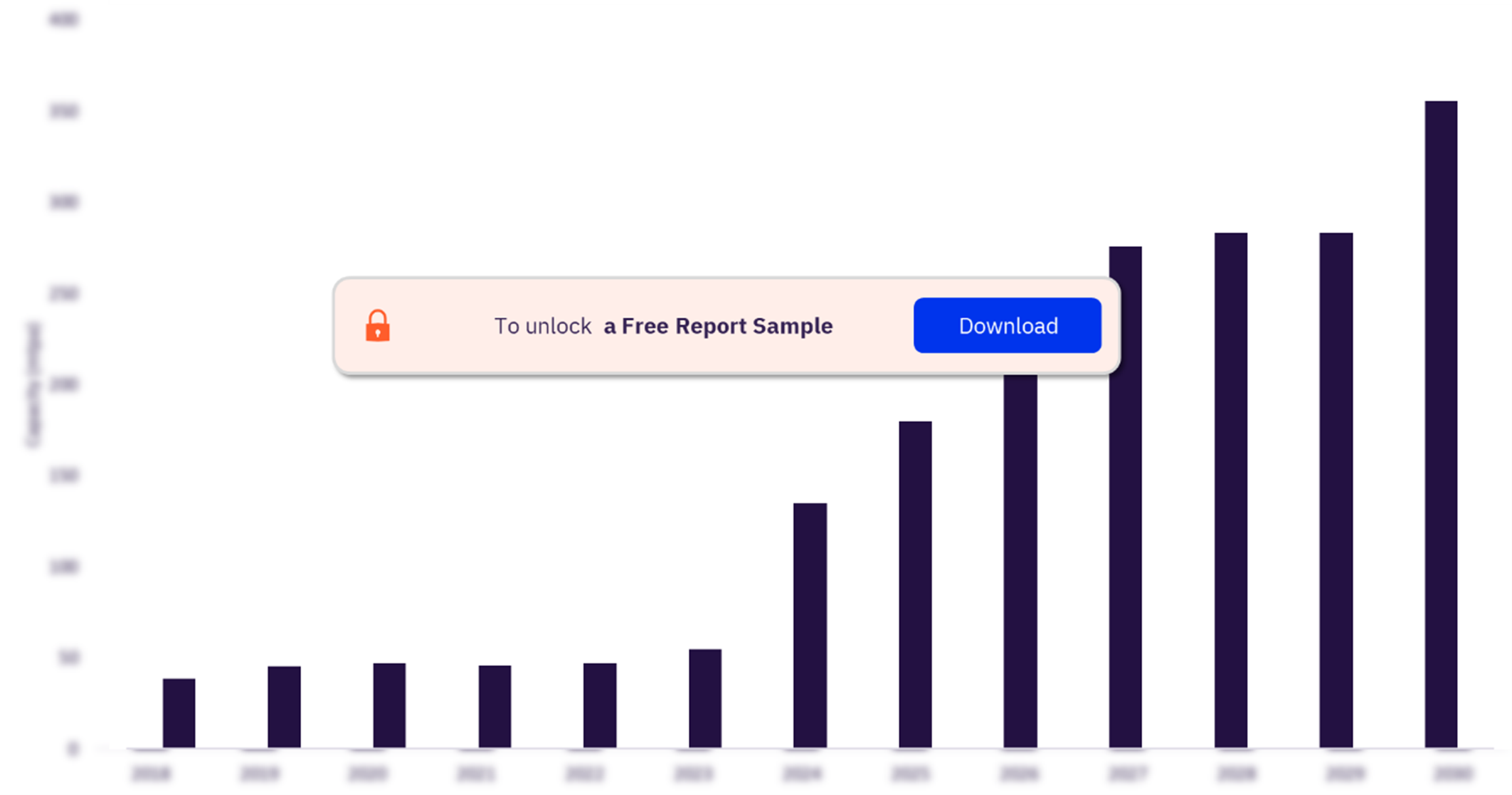

CCUS: Global carbon capture capacity is forecast to see a 30.7% CAGR from 2023-2030, with groundbreaking projects becoming operational in the next few years. manufacturers, increasing the price of steel by 10-50% when implemented into traditional coal-based DRI. Enhanced oil recovery (EOR) makes it more economically viable but contributes to further fossil fuel extraction.

Electrolysis: Electrolysis refines iron ore electrochemically by passing a current through it, rather than by direct reduction. Molten oxide electrolysis (MOE) uses a strong current giving high electrode temperatures, whereas low-temperature electrolysis (LTE) uses significantly less electricity by using an acidic or alkaline solution. The development of electrolysis technologies lags behind HDRI, but its proposed advantages have meant that it has begun to garner increased investment interest in multiple technologies. Unlikely to challenge HDRI in the near term (before 2030), but by 2050 it could begin to make up a greater share of green steelmaking.

Global Carbon Capture Capacity

Buy the Full Report for More Insights on the Decarbonising Technologies for the Steel Industry. Download a Free Sample Report

Scope

- Steel industry emissions footprint

- Suitability assessment of decarbonization technologies

- Global low carbon hydrogen outlook

- Hot direct reduced iron (HDRI) steel key players

- Global CCUS capacity outlook

- Key players refining by electrolysis

Key Highlights

- Steel contributes to 9% of CO2 emissions globally (EPRS), with coal used in the direct reduction of iron ore (DRI) being the highest emitting stage in steelmaking.

- In order to keep emissions in line with the Paris Agreement, the industry must cut emissions by 93% before 2050.

- Despite a doubling in the green steel project pipeline in the last year, an additional 30 projects are necessary to be on track to achieve the IEA’s NZE milestones.

- HDRI green steel is currently around a third more expensive than conventional steelmaking

- Electrolysis refines iron ore electrochemically by passing a current through it, rather than by direct reduction. Molten oxide electrolysis (MOE) uses a strong current giving high electrode temperatures, whereas low-temperature electrolysis (LTE) uses significantly less electricity by using an acidic or alkaline solution.

Reasons to Buy

- Obtain the most up to date information on recent developments and policies effecting the steel industry’s energy transition.

- Identify key energy transition technologies for the decarbonization of the steel industry.

- Obtain market insight into current rates of technology adoption and the factors that will shape the sector’s decarbonization.

- Identify the companies most active companies across CCUS and green steel in the sector.

Volvo Group

Hitachi Ltd

Nel ASA

Abu Dhabi National Energy Co.

H2 Green Steel

SSAB AB

Vattenfall AB

LKAB

Emirates Steel Industries

LanzaTech Global Inc.

ArcelorMittal SA

Electrasteel Inc

Amazon Inc

Boston Electrometallurgical Corporation

Table of Contents

Table

Figures

Frequently asked questions

-

Which are the key decarbonizing technologies in the Steel industry?

The key decarbonizing technologies of the steel industry are Hydrogen Direct Reduction of Iron (HDRI), CCUS, and Electrolysis

-

What does the HDRI technology involve?

HDRI replaces coal with hydrogen in reducing iron ore to yield pure iron. Instead of producing CO2 as a byproduct, hydrogen as the reducing agent produces water. Decarbonization utilizing HDRI relies on an infrastructure that supplies green hydrogen, which is produced by electrolysis of water using renewable electricity. HDRI has been proven to be viable on a commercial scale but is most convenient in that natural gas can be used as a bridging technology – already achieving 50-60% reductions in emissions in the meantime before green hydrogen becomes accessible and affordable.

Get in touch to find out about multi-purchase discounts

reportstore@globaldata.com

Tel +44 20 7947 2745

Every customer’s requirement is unique. With over 220,000 construction projects tracked, we can create a tailored dataset for you based on the types of projects you are looking for. Please get in touch with your specific requirements and we can send you a quote.